A Step-by-Step Guide to Custom Sheet Metal for the Home

The journey from envisioning custom sheet metal elements to seeing them seamlessly integrated into your home is a collaborative and meticulous process. At Michaels Sheet Metal, we dedicate ourselves to transforming your ideas into reality, offering products and experiences that elevate the aesthetic and functionality of your living space. Explore the possibilities with Michaels Sheet Metal, where craftsmanship meets creativity.

In this guide, we’ll take you through the fascinating journey of custom sheet metal fabrication for your home, providing insights and knowledge to help you make informed decisions.

Step 1: Understanding Your Needs

At Michaels Sheet Metal, every home and its requirements are unique. Begin by assessing your needs—whether it’s a custom range hood, decorative panels, or a personalized backsplash. Understanding your specific requirements will guide the entire fabrication process.

Step 2: Material Selection

Sheet metal comes in various materials, each with its characteristics. At Michaels Sheet Metal, we offer options like stainless steel, aluminum, and copper. Consider factors like durability, appearance, and maintenance when selecting the best material that suits your home.

Step 3: Designing the Blueprint

Once your requirements and material choices are defined, creating a detailed blueprint is the next step. Our skilled designers at Michaels Sheet Metal work closely with you to ensure the design aligns with your vision and meets practical needs. From intricate patterns to minimalist designs, we turn your ideas into tangible plans.

Step 4: Precision Cutting and Shaping

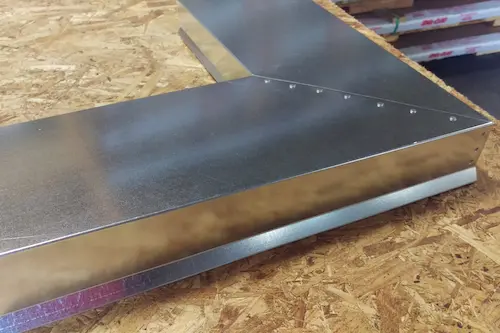

With the blueprint, our artisans meticulously cut and shape the chosen sheet metal. Precision is critical to achieving the desired aesthetic and functionality. At Michaels Sheet Metal, our cutting-edge equipment ensures accuracy in every detail, giving life to your custom design.

Step 5: Forming and Bending

Sheet metal’s malleability allows us to create unique shapes and forms to suit your design. Our skilled artisans use advanced techniques to bend and form the metal, bringing your vision to life. Whether a sleek countertop or an ornate wall feature, Michaels Sheet Metal delivers precision and excellence.

Step 6: Welding and Joining

Seamless joins and sturdy connections are crucial in sheet metal fabrication. Michaels Sheet Metal employs skilled welders to ensure the structural integrity of your custom pieces—our commitment to quality guarantees that your sheet metal creations withstand the test of time.

Step 7: Finishing Touches

The finishing touches transform a sheet of metal into a work of art. Whether it’s a polished surface, a brushed texture, or a protective coating, Michaels Sheet Metal pays attention to every detail. The goal is not only to enhance aesthetics but also to provide long-lasting protection against environmental elements.

Step 8: Installation

At Michaels Sheet Metal, we deliver a seamless installation process. Our experienced team ensures that your custom sheet metal pieces fit perfectly into your home, creating a harmonious blend with your existing decor.

Step 9: Maintenance Tips

To preserve the beauty and functionality of your Custom Sheet Metal elements, it’s essential to follow proper maintenance practices. Michaels Sheet Metal provides practical tips and guidance on caring for your investment, ensuring its longevity and continued appeal.

The journey from envisioning custom sheet metal elements to seeing them seamlessly integrated into your home is a collaborative and meticulous process. At Michaels Sheet Metal, we dedicate ourselves to transforming your ideas into reality, offering products and experiences that elevate the aesthetic and functionality of your living space. Explore the possibilities with Michaels Sheet Metal, where craftsmanship meets creativity.