Can Metal Roofing Be Used as Siding? Pros, Cons & Expert Tips from Michaels Sheet Metal

The short answer: yes. Metal roofing panels can absolutely serve as siding — and in many cases, they provide exceptional performance, longevity, and aesthetic value when applied correctly. But the decision requires careful consideration of materials, finishes, panel profiles, and installation techniques.

As sheet metal fabrication experts with decades of experience in Los Angeles and Southern California, here’s our comprehensive guide on using metal roofing as siding — including benefits, challenges, and best practices.

Why Metal Roofing Panels Are Suitable for Siding Applications

Metal roofing panels are engineered to endure some of the most extreme environmental conditions — including UV exposure, heavy rains, salt air, and high winds. These same characteristics make them a smart choice for vertical wall cladding, especially in the variable climate zones of Southern California.

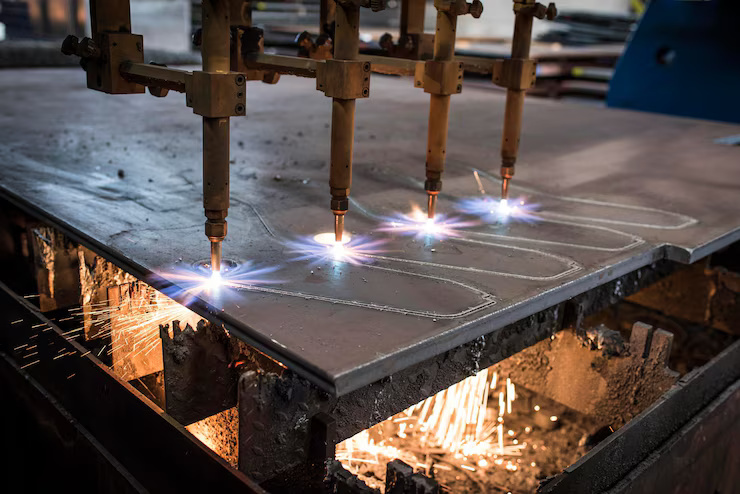

From standing seam to corrugated profiles, metal roofing systems bring durability, style, and sustainability to modern siding applications.

Advantages of Using Metal Roofing as Siding

- 1. Exceptional Durability

Metal siding resists warping, cracking, mold, termites, and fading — making it one of the most reliable siding materials on the market. With proper installation and finish, it withstands the intense heat of inland LA or the salty air of the coast. - 2. Low Maintenance

Unlike wood or fiber cement, metal requires minimal upkeep. Periodic rinsing and inspection are typically sufficient, reducing the long-term cost of ownership. - 3. Architectural Appeal

Clean lines and sleek profiles make metal siding a popular choice among architects and designers. It complements both contemporary homes and commercial buildings, offering a bold, modern look. - 4. Sustainability

Most metal panels are manufactured from recycled content and are themselves 100% recyclable. This supports LEED credits and green building standards. - 5. Fire Resistance

In wildfire-prone areas like California, the non-combustible nature of metal siding provides added safety and peace of mind.

Key Considerations Before Using Metal Roofing as Siding

- 1. Thermal Expansion & Contraction

Metal expands and contracts with temperature shifts. Proper fastening systems and spacing are essential to accommodate this movement and prevent panel distortion or oil canning. - 2. Installation Complexity

Flashing, alignment, ventilation, and moisture control must be carefully addressed. Unlike basic siding installations, this process requires expertise in building envelope systems and metalwork — exactly what we specialize in. - 3. Initial Cost

While metal siding offers a superior lifespan, the upfront cost is typically higher than vinyl or fiber cement. However, reduced maintenance and replacement costs offer strong ROI over time. - 4. Sound Transmission

Metal can conduct sound. For noise-sensitive areas, we recommend pairing panels with a thermal or acoustic barrier layer.

Recommended Metal Panel Profiles for Siding

- • Standing Seam Panels – Known for sleek vertical lines and hidden fasteners. A favorite for modern residential and commercial facades.

- • Flush Wall Panels – Minimalist, smooth surfaces with concealed fasteners, ideal for contemporary designs.

- • Corrugated Panels – Traditional wavy appearance, often used for industrial or agricultural aesthetics.

- • Custom Panels – Tailored designs and finishes based on unique architectural requirements.

Each panel system is reviewed for structural integrity, moisture resistance, and aesthetic compatibility.

Applications Across Project Types

- • Modern Homes – Accents or full facades using standing seam or flush wall panels.

- • Commercial Buildings – Metal siding delivers a professional and high-end appearance for offices and retail spaces.

- • Industrial & Agricultural Structures – Corrugated panels offer durability with a rugged, practical style.

- • Mixed Material Designs – Combine metal with wood, stone, or glass for contrast and architectural depth.

Installation Best Practices

- Install breathable weather barriers to prevent moisture buildup.

- Plan for water drainage through proper weep paths.

- Use concealed fasteners where possible to preserve aesthetics and avoid corrosion points.

- Account for panel orientation — vertical panels emphasize height, while horizontal lines can widen a structure visually.

- Select high-performance, UV-resistant coatings suitable for intense LA sun exposure.

Michaels Sheet Metal: Expert Support from Design to Delivery

Unlike generic suppliers, Michaels Sheet Metal provides end-to-end support for projects using metal roofing panels as siding. From material selection and fabrication to installation and aftercare, our approach is tailored, precise, and performance-driven.

Get Started

For any questions or concerns, get in touch with our knowledgeable staff today. We would be glad to assist you!

Contact Us TodayOur in-house fabrication shop in Los Angeles allows us to:

- Customize panels to project-specific dimensions

- Ensure accurate color matching for roof and wall systems

- Meet structural load requirements and local building codes

- Collaborate directly with architects, builders, and installers

We don’t just provide panels—we deliver confidence.

Expert Tips for Using Metal Roofing as Siding

- ✔ Choose metal types and coatings suitable for your climate (e.g., Galvalume or painted aluminum in coastal zones).

- ✔ Verify panel systems are rated for wall applications, not just roofing.

- ✔ Incorporate trim pieces and flashings for watertight performance and aesthetic detailing.

- ✔ Don’t overlook the role of insulation and underlayment for energy efficiency and noise control.

Frequently Asked Questions

- Q1: Is metal roofing as siding more expensive than traditional siding materials?

A: Yes, the initial cost is higher, but long-term savings from low maintenance and longevity offer better value over time. - Q2: Can all metal roof panels be used for siding?

A: Not all. Some profiles are designed strictly for roof slopes. We help you select those engineered for vertical use. - Q3: Will metal siding rust near the ocean?

A: With proper coating, such as marine-grade painted aluminum or Galvalume, corrosion is minimized even in coastal environments. - Q4: Can I match my siding and roof using the same panels?

A: Absolutely. Many clients use the same material for both, ensuring a seamless visual transition. - Q5: How long does metal siding last?

A: Depending on the metal type and finish, you can expect 40 to 70 years of reliable performance.

Ready to Explore Metal Roofing as Siding?

If you’re a homeowner, architect, or builder in Los Angeles looking to explore high-performance, custom-fabricated metal siding solutions, reach out to Michaels Sheet Metal today.

We’re proud to help elevate your building’s exterior with precision-crafted metalwork that’s made to last.

Thinking of using metal roofing as siding? Talk to the experts at Michaels Sheet Metal for custom solutions and design support!