Sheet Metal Processing Techniques in the Construction Industry

Welcome to Michaels Sheet Metal, a leading provider of innovative sheet metal solutions for the construction industry. This article will explore the various sheet metal processing techniques that play a crucial role in construction projects. At Michaels Sheet Metal, we are committed to delivering superior results that meet the unique needs of our clients, leveraging our expertise and dedication to quality. Join us as we delve into the significance of sheet metal processing in construction.

1. Laser Cutting:

Laser cutting is a precise and efficient sheet metal processing technique in the construction industry. With advanced laser technology, Michaels Sheet Metal can accurately cut various sheet metal materials, including steel, aluminum, and stainless steel. Laser cutting offers several advantages, such as high precision, minimal material wastage, and the ability to create intricate and complex designs. This technique enables us to fabricate components and structural elements accurately, ensuring a perfect fit and enhanced construction efficiency.

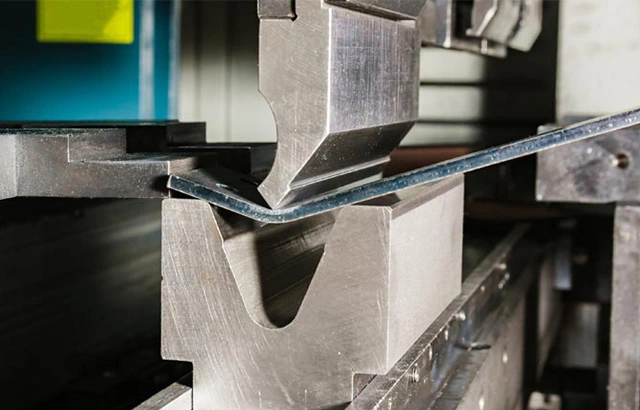

2. Bending and Forming:

Bending and forming are essential techniques Michaels Sheet Metal employs to shape sheet metal into the desired configurations for construction projects. Using state-of-the-art machinery and skilled artisans, we can accurately turn and form sheet metal to meet specific design requirements. This process allows us to create custom components, such as ductwork, flashing, and architectural features, ensuring seamless integration into the overall construction. Bending and forming techniques offer flexibility, allowing for the creation of complex shapes and angles, which are vital in modern construction designs.

3. Welding and Joining:

Welding and joining techniques are crucial in sheet metal processing for construction applications. At Michaels Sheet Metal, we possess expertise in various welding methods, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. These techniques enable us to securely join sheet metal components, ensuring structural integrity and durability. Welding is vital for fabricating large-scale structures like frameworks, supports, and enclosures, providing strength and stability to the overall construction. Our skilled welders follow industry best practices to deliver high-quality welds that meet the most stringent construction standards.

4. Finishing and Surface Treatment:

In the construction industry, sheet metal components often require appropriate finishing and surface treatment to enhance their durability and aesthetics. Michaels Sheet Metal offers a range of finishing techniques, including powder coating, painting, and galvanizing. Powder coating provides a durable and attractive finish while protecting the sheet metal from corrosion and wear. The image allows for customization and color matching to suit the design requirements of the construction project. Galvanizing is a process that adds a protective zinc coating to the sheet metal, providing superior resistance against corrosion. By utilizing these finishing techniques, Michaels Sheet Metal ensures that the fabricated components meet functional requirements and enhance the visual appeal of the construction project.

As a prominent player in the sheet metal industry, Michaels Sheet Metal understands the significance of sheet metal processing techniques in the construction sector. Through laser cutting, bending and forming, welding and joining, and finishing and surface treatment, we deliver high-quality sheet metal components that meet the unique needs of construction projects. Our commitment to precision, efficiency, and innovation enables us to contribute to the success of diverse construction ventures, ranging from residential buildings to commercial structures. Choose Michaels Sheet Metal for your construction sheet metal needs, and experience the benefits of our advanced processing techniques and unparalleled craftsmanship. Together, let us build a solid foundation for your construction dreams.