Why You Should Choose Laser Cutting For Sheet Metal Fabrication

At Michaels Sheet Metal we take pride in providing fabrication services.

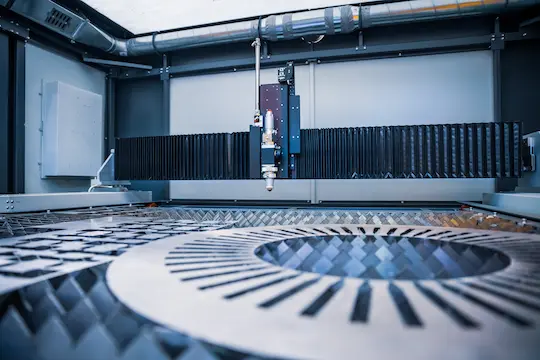

Laser cutting has emerged as the technique to achieve efficient results, which truly set us apart.

At Michaels Sheet Metal, our dedication to this technique stems from our unwavering commitment to delivering unparalleled quality and pushing the boundaries of what’s possible. Join us in embracing the laser-cut path to excellence, where metal transcends its physical form and becomes a testament to artistry.

1. Introduction: Unveiling the Artistry of Michael Sheet Metal

Welcome to the realm of Michaels Sheet Metal, where metal fabrication is a process and an art form. Our dedication to excellence has earned us a reputation that resonates with craftsmanship, innovation, and unparalleled quality. In this article, I’ll explore why I firmly stand by laser cutting as the prime technique for our sheet metal fabrication endeavors.

2. Precision Redefined: Laser Cutting at Its Finest

When it comes to sheet metal fabrication, precision is non-negotiable. Laser cutting, a technique that employs high-powered lasers to cut through metal with utmost accuracy precisely, epitomizes the pinnacle of precision. At Michaels Sheet Metal, we understand that even the slightest deviation from specifications can lead to compromised products and unsatisfied clients. Laser cutting ensures that every cut is immaculate, every angle is exact, and every product is a testament to meticulous craftsmanship.

3. Seamless Customization: Tailoring Metal to Your Vision

One of the standout advantages of laser cutting is its versatility. Whether you need intricate designs or large-scale patterns, laser cutting offers a level of customization that knows no bounds. Our team at Michaels Sheet Metal revels in transforming your visions into reality. From creating decorative architectural elements to crafting functional components with intricate geometries, laser cutting empowers us to fulfill your unique requirements down to the last detail.

4. Efficiency Amplified: Faster Turnaround, Greater Satisfaction

Time is of the essence in the world of fabrication. Laser cutting accelerates the production process without compromising on quality. The speed and efficiency of laser cutting allow us to meet tight deadlines and ensure on-time project delivery at Michaels Sheet Metal. Obtaining the finest quality products precisely when needed, without compromise, provides clarity about the subject.

5. Minimal Material Waste: Sustainability in Action

Sustainability isn’t just a buzzword; it’s a responsibility we take seriously. Laser cutting minimizes material waste by optimizing the cutting process. The precision of lasers ensures that cuts are made with minimal excess, resulting in efficient material usage. At Michaels Sheet Metal, we deeply embed our commitment to eco-friendly practices in every facet of our operations, and laser cutting aligns perfectly with our green initiatives.

6. Innovative Possibilities: Pushing Boundaries with Laser Precision

At Michaels Sheet Metal, innovation is the heartbeat of our craft. Laser cutting opens doors to innovative design possibilities that were once deemed unattainable. The ability to intricately etch, perforate, and shape metals unlocks a new realm of creativity. From artistic installations that captivate the eye to functional components that defy convention, laser cutting empowers us to push the boundaries of what’s achievable.

7. Unparalleled Quality: Elevating Industry Standards

Laser cutting doesn’t just meet industry standards; it sets new benchmarks for quality. Michaels’s Sheet Metal is not content with mediocrity. Our pursuit of excellence is evident in our products, and laser cutting plays a pivotal role in upholding these standards. Each cut, each piece, and each project is a testament to our commitment to providing nothing but the best.

As the spokesperson for Michaels Sheet Metal, I can confidently assert that laser cutting is the pinnacle of sheet metal fabrication. Its precision, customization capabilities, efficiency, sustainability, and innovative potential make it ideal for turning metal into masterpieces.

In sheet metal fabrication, laser cutting isn’t just a method—it embodies our passion for perfection at Michaels Sheet Metal.